Complex Metal Components Using Investment Casting

Superior Metal Components

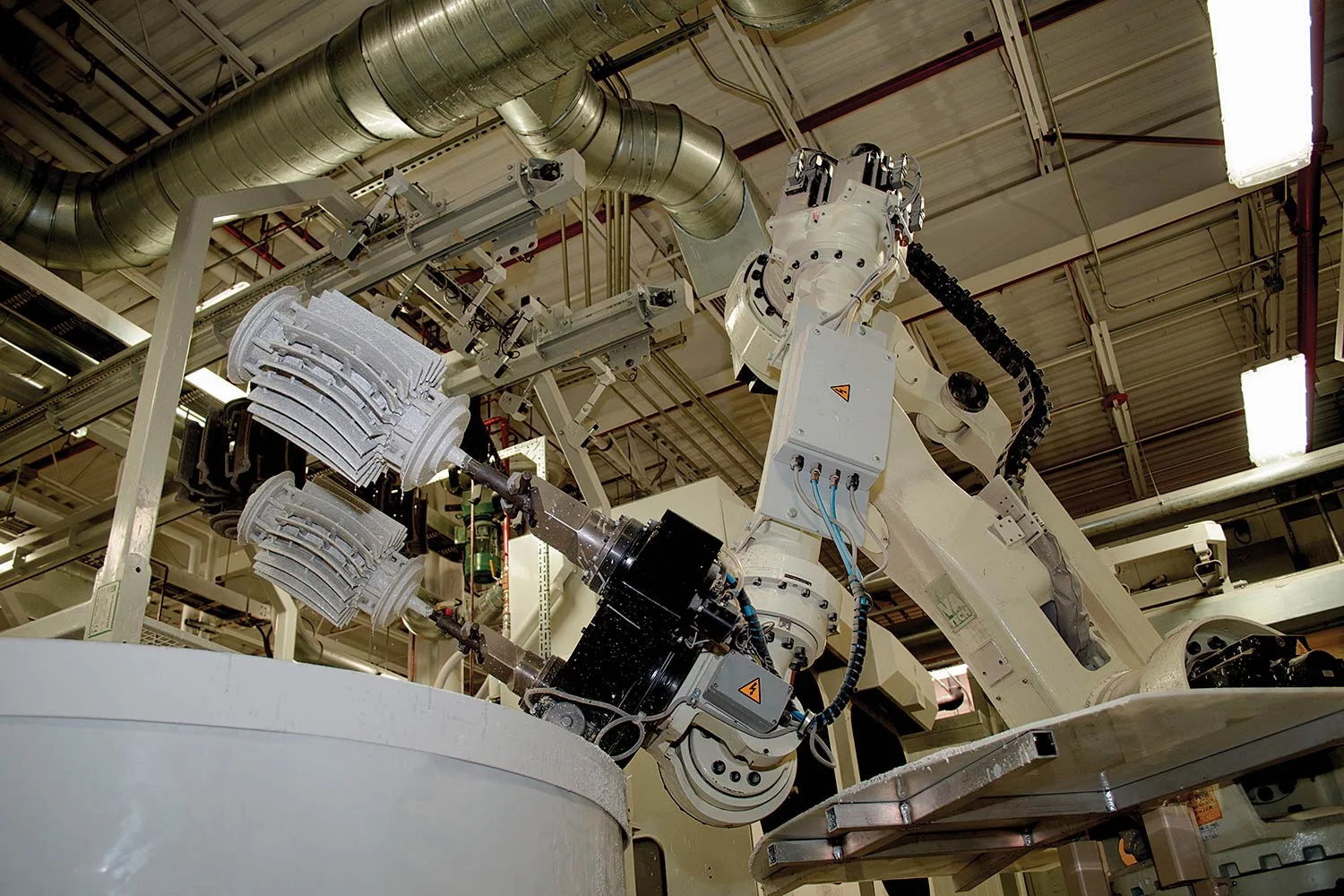

Hitchiner believes that finding a better way to make a superior product is worth the investment. Hitchiner has chosen to utilize, develop, and enhance the investment casting process, and as a result has found it has many advantages in efficiently producing complex metal components. Hitchiner is the premier supplier of complete-to-print, high-volume, complex thin-wall investment castings and fully-finished casting-based subassemblies and components to industry, thanks in large part to the quality of product our investment casting technology.

Design flexibility

Investment casting produces near-net-shape configurations, offering designers and engineers the freedom to design in a wide range of alloys. The process is capable of producing precise detail and dimensional accuracy in parts weighing many pounds or just a few ounces.

- Wide choice of alloys - Many dozens of ferrous alloys are routinely cast at Hitchiner.

- Elimination of tooling setup - By offering near-net-shape configuration, fixturing costs are substantially reduced or eliminated.

- Reduction of production costs - Costly machining operations are reduced and often eliminated. No capital equipment investment is needed to produce parts in-house.

- Reduction of assembly operations - Several parts can be made as one casting, reducing handling, assembly and inspection costs.

- Reproduction of fine details - Splines, holes, bosses, lettering, serrations and even some threads can be cast.

View a Process Comparison Chart